Hydro Jet Drain Cleaning

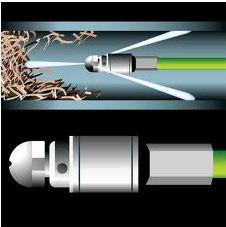

Pipe cleaning is commonly performed by a technique known as hydro Scrubbing or hydro jetting. The application of streams of high pressure water for use within pipes for cleaning & debris removal. Water at the correct high pressure can cut roots, dissolve blockages, emulsify grease and soaps while spray washing pipe wall surfaces. As part of the hydro-jetting process, the water from the nozzle can also wash away accumulated dirt or debris on the bottom of the pipe at the same time.

Hydro jetting or Scrubbing in Sonoma County and local Area is the process of using water under high pressure to scour the pipe walls clean of grease, debris, roots, sand or dirt and flush it all out and away downstream.

Jetting is unique in that it is the only process that can actually clean your lines. Because of this, hydro jetting has become the industry standard for sewer and Storm Drains.

This is in complete contrast to running a cable or a snake in a line. A cable or snake typically punches a hole in the debris or blockage to allow flow again and usually leaves some debris behind. This debris can be and often is the starting point for debris to start accumulating all over again.

The majority of pipes that need hydro Scrubbing or have potential applications for hydro jetting are:

Hydro Jetting Sanitary or Mainline Sewers: located under streets and roads that connect building laterals to a municipal waste water treatment plant for treatment. Waste water flows freely through sewers via gravity. Sewers are connected at various intervals by manholes (maintenance access point) that in some applications will allow for a change of direction of waste water flow. Municipal sewers can range in size from pipes as small as 6 inches, increasing in diameter as more & more laterals connect to the system. Sewer blockages can form as a result of root infiltration, food grease buildup, soap residue buildup, dirt and debris accumulation. Blockages can also occur from pipe failure or collapse that will require excavation to correct. Private sanitary waste water collection systems of similar construction can be found on privately owned property connecting buildings in apartment and office complexes, universities or other large campus-type facilities that ultimately discharge into a municipal waste water systems.Hydro Jetting Laterals – Pipes that connect building drainage systems to municipal sewers, considered to be part of the property and the responsibility of the property owner. Typically, laterals are 4 & 6 inch diameter pipes that connect directly to municipal sewer pipelines, but can be larger for commercial or industrial buildings. Lateral blockages can form as a result of root infiltration, food grease buildup, soap residue buildup, dirt and debris accumulation. Blockages can also occur from pipe failure or collapse that will require excavation to correct.

Hydro Jetting Drains – Drainage pipes are located under or within buildings, are considered to be part of the property and the responsibility of the property owner. Drains in buildings can range in sizes from 2 inch to 6 inch diameters (typically) that normally contain “Tees” or “Elbows” for waste water directional changes. Drain blockages can form as a result of food grease buildup, soap residue buildup, dirt and debris accumulation.

Hydro Jetting Storm Drains – pipes that are limited to the collections and control of rainwater. Rainwater can be collected and directly diverted to streams or rivers without passing through a water treatment plant. Storm drain blockages can form as a result of root infiltration, silt, dirt and debris accumulation. Blockages can also occur from pipe failure or collapse that will require excavation to correct.

Hydro Jetting Process Pipe & Conduits – Pipes of all diameters & lengths used in manufacturing plants, chemical plants & food processing facilities that transports liquids other that sanitary waste water or rainwater. Blockages in process pipelines can be caused by many factors related to the process, each individual application occurrence will have unique factors to be dealt with on a case by case basis. Hard scale mineral buildups found inside of pipes will reduce overall pipe flow capacity. High pressure water at the correct pressure can remove any scale buildup no matter how irregular without damage to the original pipe.

Why Hydro Jetting is Better

Before Hydro JettingAll of the above types of pipe systems are susceptible to blockages and thus inconvenient backups or potential economic loss. Blockages can occur from the buildup of debris over a period of time, ingress of root infiltration or from foreign debris introduced into the pipeline (accidentally or maliciously). No matter what type of debris that is the cause of a blockage; high pressure jetting is the preferred method of re-establishing water flow. High pressure jetting not only removes a blockage but washes away all debris found within a pipe. Using high pressure water is faster and less physically labor intensive than use of a mechanical rodding or cable machine. Hydro-jetting units maintain constant working pressure and cleaning power at the nozzle end.

After hydro jetting

Mechanical machines will lose cutting and torque power as rod or cable distances increase within pipelines from the point of entry. High pressure jetting has another advantage over cable or rodding machines. Where access is difficult, a lightweight, flexible jet hose is a safer and more practical solution. Pipelines that are suspended from ceilings or catwalks are easily cleaned using a high pressure jetting hose rather than a heavy, cumbersome mechanical drain cleaning machine. Cleaning vertical stacks or vents is easier with a high pressure jetting unit and lightweight jetting hose than with heavy drain cleaning cables or rods.

Over the past 70 years sewer & drain lines have been installed with little or no attention paid to routine pipeline maintenance. The “bury and forget” or “out of sight, out of mind” attitudes toward sewer lines has now led to a growing maintenance and rehabilitation industry. With increased collection system integrity & environmental concerns, inspection of waste water collection systems has become a major market application for hydro-jetting units. Hydro-Jetting of sewer and drain pipelines with high pressure water prior to televised inspection(CCTV) surveys for determination of pipeline structural integrity is now a recognized standard operating procedure. Hydro-jetting and CCTV inspection of laterals and pipes under buildings for structural defects is also growing in demand, especially at the time of property transfers.

Why Choose GAC Company to Perform Your Hydro-Jetting

We operate a wide variety of Jetters from small to full size trailer mounted US Jetting machine carrying a standard of 500 feet of 1/2 inch hose. These machines deliver a maximum 4000 psi at 18 gallons per minute. The pressure is completely adjustable for any given situation. We maintain a variety of hoses that allow us to hydro-jet anything from a 36 inch main sewer line all the way down to a small 2 inch trap in a floor drain. We also use Warthog brand rotary nozzles when possible because they are so much more efficient at cleaning even though they are ten times the cost of a non-rotary nozzle. We have thousands of hours of specific Hydro-Jetting experience and it is truly amazing what a full size hydro-jetting unit with a rotary head will cut through and flush out.

Call for a FREE estimate on Hydro-Jetting your Sewer or Drain lines